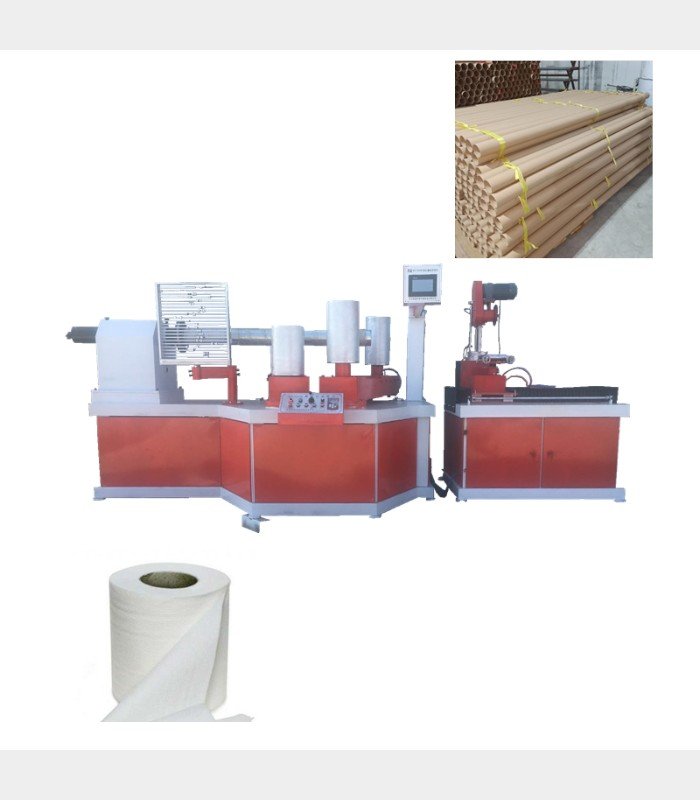

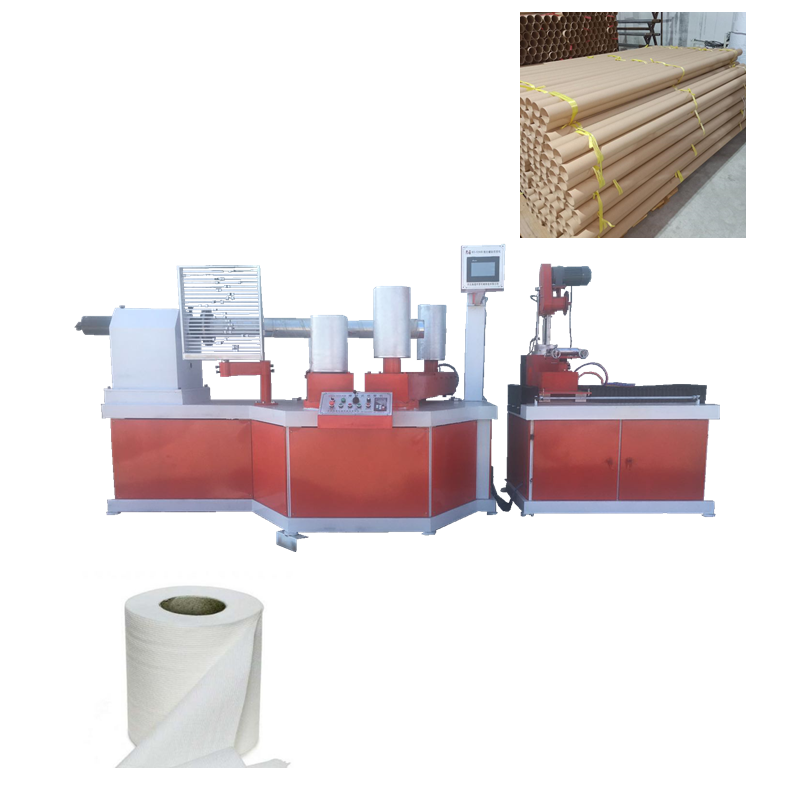

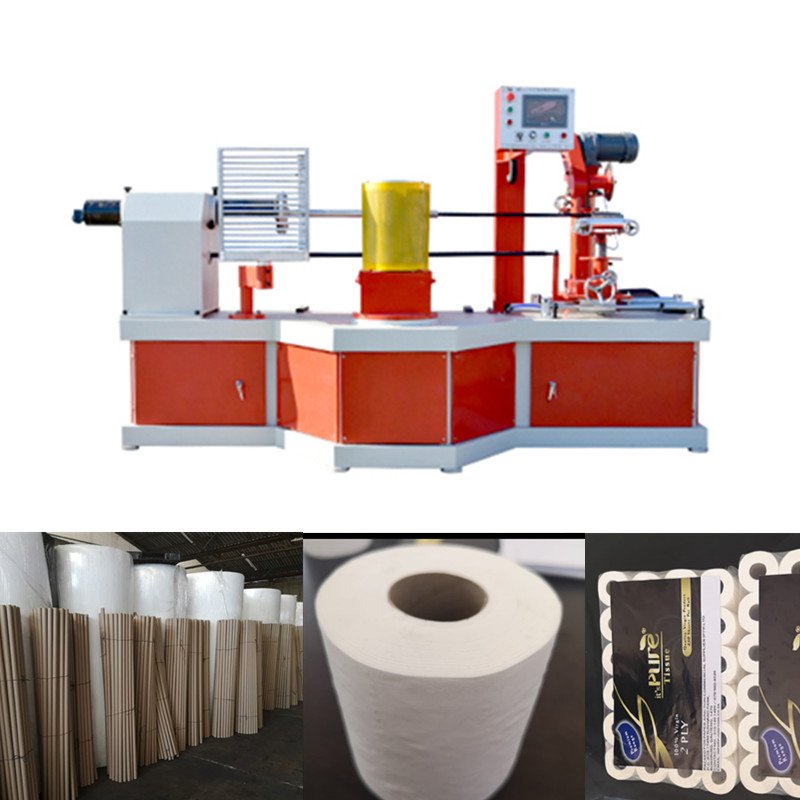

ShenZe Paper tube machine

PACKAGE: Plywood case or in proper way

VALIDITY: 15days

PAYMENT TERM:TT in advance

30% as down payment,

70% made before delivery by the advice of seller’s photos.

LEAD TIME: 15 days after advance deposit received

QUALITY GUARANTEE: The seller will, without charge, offer replacement for defective parts which is caused by product quality in one year. Lifelong service is offered at cost.

Functions:

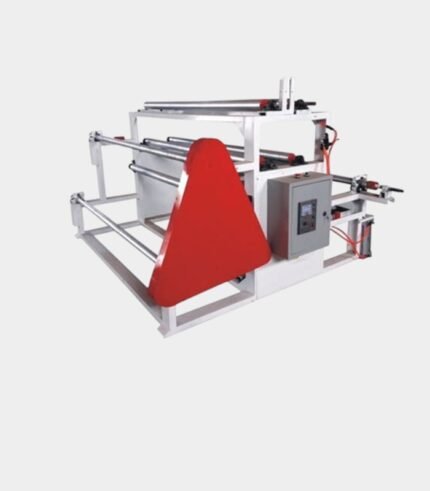

This automatic paper core making machine can make the paper core from fluting paper roll .the paper roll have been cut into with small width.It can coat glue on paper and rotate into paper core.

Features:

1. frequency control system,low noise;

2.Saving power,it can save 50% electricity than ordinary electromagnetic speed adjustment;

3.Locating by infrared ray,automatic cutting;

4.Single blade or saw blade are in common use,adjust the cutting length of the paper core arbitrarily;

5.Automatic Gluing,easy operation

6.The digital control panel set various operating function,can set arbitrary workings on the machine;

Technical Specification:

|

Technical Specification |

Control System |

|||||

|

Roll paper layers |

2-10layers |

PLC control |

Extra cost USD950 |

|||

|

Max. diameter |

150mm |

Human-computer interface |

Color Touch Screen |

|||

|

Min. diameter |

20mm |

Program version |

HT/4.0 |

|||

|

Max. thickness |

8mm |

Frequency converter |

Shenzhen Easydrive Frequency |

|||

|

Min.thickness |

0.5mm |

Execute device(contactor) |

China Zhengtai Product |

|||

|

Fixed mode of coil core mould |

Flanged flange |

signal element(photoelectric switches) |

Omron products |

|||

|

Rolling head |

Two heads single belt |

Pneumatic element |

Hengyi Products |

|||

|

Cutting method |

Single round knife cutting without resistance |

Adjustable Angle of the motor |

Jiacheng |

|||

|

Gluing method |

Single side/double sides gluing |

Synchronous control |

X axis servo screw and Z axis stepping screw |

|||

|

Fixed-length mode |

photoelectricity |

Simultaneous tracking of the cutting pipe system |

Servo synchronous tracking cutting |

|||

|

Operator |

1-2persons |

Equipped Device |

||||

|

Paper core rolling speed |

3-20m/min |

Remote control |

selectional |

|||

|

Speed control |

Frequency converter |

Auto core dropping shelf |

Yes |

|||

|

Power supply |

380V three phase(can be customized) |

Belt diagonal |

Electric |

|||

|

Specification Size |

Belt tightening adjustment |

Mechanical adjustment |

||||

|

Machine size:L*W*H |

3200*2000*1950mm |

The host angular |

Selectional |

|||

|

Floor Space:L*W |

16*7.5m |

Lacking-paper automatic stop |

Automatic stop of the bottom paper |

|||

|

Hub diameter |

269mm |

Automatic feed glue |

Pneumatic diaphragm pump |

|||

|

Hub height |

400mm |

Paper tape is automatically used for lubricating oil |

Automatic |

|||

|

Min.wheel distance |

750mm |

Tension adjustment |

Mechanical adjustment |

|||

|

Max.wheel distance |

950mm |

Paper frame type |

the whole paper frame |

|||

|

Weight |

2800kg |

Rolling belt |

Canvas belt/strip baseband |

|||

|

Drive System |

Attached parts |

|||||

|

Host Power |

5.5kw |

Volume tube plug |

1pcs |

|||

|

Wheel speed |

47r/min |

Tube belt |

1set |

|||

|

Wheel hub output torque |

1360N.m |

Application tool |

yes |

|||

|

Drive method |

Gear drive and chain drive |

Surface paper installation |

yes |

|||

|

Drive chain model |

12A x 2 |

|||||

|

Wheel hub drive |

Two wheel drive |

|||||

|

Cutting blade motor |

Stepping motor/gear motor |

|||||

|

Bearings |

Harbin bearings |

|||||

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Reviews

There are no reviews yet.